How Different Types of Inductors Used in The Electronic Industry

In electronic component products,

inductors play a pivotal and very important role in maintaining the normal

operation of electronic equipment. Inductors are now widely used in high-power

electrical appliances, spike blockers, RF devices, signal shielding and other equipment.

The following are the common types of inductors and their typical usage:

Coupled Inductors

The magnetic circuit of the coupled

inductor is shared and affects each other. Coupled inductors are commonly used

in transformers, especially for feedback mechanisms for voltage rise and fall

or isolation. Transformers are included.

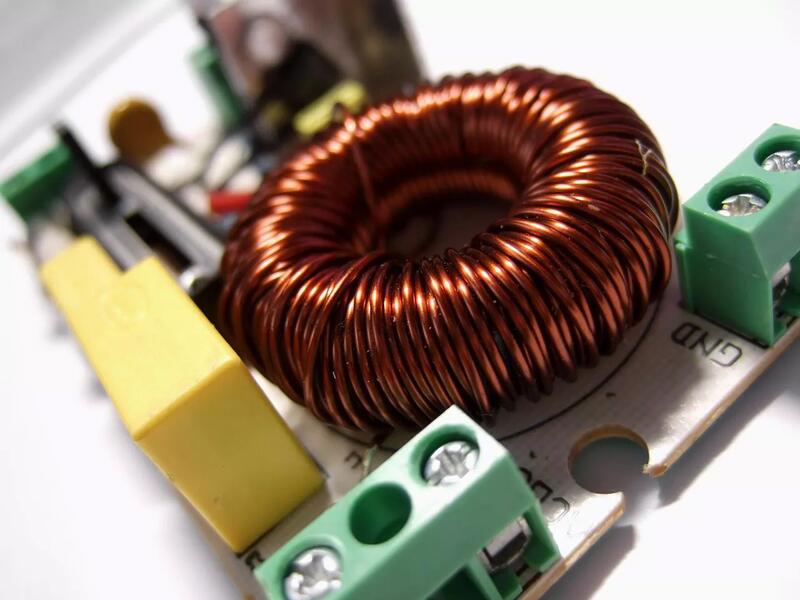

Winding Core Inductors

Winding Core Inductors is characterized

by having one or two winding cores. The number of windings is proportional to

the increase in inductance and capacitance. It should be noted that there is an

effective trade-off between high inductance and maximum operating frequency.

Power Inductors

Power inductors usually have a variety

of power and size. The current carried by these inductors ranges from a few

amperes to tens of hundreds of amperes. Because power Inductors can withstand a

large amount of current, they can generate a strong magnetic field. At the same

time, in order to prevent these magnetic fields from causing unnecessary noise,

it is necessary to use corresponding shielding measures. SAT Amorphous has rich

experience in shielding measures. Through the factory's own aluminum parts

processing plant, it can effectively solve the noise problem while providing high

performance nanocrystalline power Inductors.

RF Inductors

RF (Radio Frequency) inductors usually

operate in high frequency environments. This type of inductor usually has high

resistance and low current rating. Due to the operating frequency of the

inductor, it is important to reduce multiple loss sources, so most RF inductors

use a hollow structure. The reason why ferrite is not used is that its loss

will increase during use. Therefore, the nanocrystalline material made by SAT

Amorphous has a great advantage over ferrite, which can effectively reduce the

loss and increase permeability.

Chokes

Chokes can block high frequency pulses

while letting low frequency pulses through. There are usually two categories:

• Nanocrystalline core power supply and

audio chokes. SAT Amorphous has relatively mature experience in choke

manufacturing and is a supplier to international groups such as ABB and SMA (SAT Global Strategy Partners)

• RF choke using iron powder

core.

Different Types of Inductor Cores

Because the core material directly

affects the following three aspects:

1. Inductance value,

2. Maximum operating frequency,

3. Current capacity.

Therefore, the performance of the

inductor usually depends on the core material.

• Air Core- High operating

frequency, low inductance.

• Iron Core- Low resistance,

high inductance. Core loss, eddy current, magnetic saturation and hysteresis

will limit performance.

• Ferrite Core- Magnetic

saturation limits the current capacity.

• Nanocrystalline Winding Core- SAT Amorphous Toroidal

core or c cut core, can provide high inductance, high permeability, low

magnetic loss.